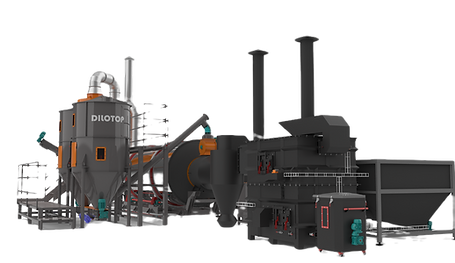

DILOTOP Industrial Dryers

Industrial Drum Dryers for Biomass, Wood Sawdust, Wood Chips & Agro Commodities

High-efficiency drying systems engineered for consistent moisture reduction, low operating costs, and reliable performance across a wide range of bulk materials.

At DILOTOP, we specialize in the engineering, production, and supply of industrial drum dryers and complete drying lines for wood biomass, sawdust, wood chips, agricultural commodities, biogas plant sludge, mineral materials, and other bulk products. Each dryer is designed according to the customer’s material, required moisture output, and production capacity to achieve maximum efficiency and stable long-term operation.

What SPB Drum Dryers Are and Where They Are Used

SPB drum dryers operate on the principle of continuous rotation, where material is mixed, transported, and exposed to a stream of hot air. This enables fast, uniform, and controlled drying suitable for a wide range of production environments.

Typical applications include:

-

Wood sawdust and wood chips

-

Biomass and bio-based materials

-

Agricultural commodities (grains, legumes, corn, hops, hemp)

-

Digestate and sludge from biogas plants

-

Plastic regrind and recycling materials

-

Sand, gravel, and other mineral aggregates

Key Advantages of SPB Drum Dryers

SPB dryers are designed to deliver consistent performance and long-term operational reliability.

Main advantages:

-

High drying efficiency and stable output moisture

-

Robust industrial construction using European materials

-

Low operating and maintenance costs

-

Modular design, adaptable to different production layouts

-

Compatible with pelletizing and briquetting lines

-

Suitable for a wide range of bulk materials

How an SPB Drum Dryer Works (Operating Principle)

SPB dryers use a proven technology based on controlled airflow and mechanical mixing inside a rotating drum.

Basic process flow:

-

Material feeding via screw, belt, or pneumatic conveyor

-

Drying inside the rotating drum, with continuous mixing

-

Hot-air generation using an industrial hot-air furnace or boiler

-

Separation of dust and particles using cyclones or filter units

-

Moisture control through automated regulation

-

Discharge of dried material into subsequent processing equipment

This setup ensures uniform drying, high throughput, and stable operation in continuous production.

Available SPB Dryer Variants

The SPB series is available in several configurations to meet different installation and energy requirements.

SPB Standard Series – Modular Drum Dryers

-

Traditional modular design suitable for most production layouts

-

Available capacities: SPB2, SPB5, SPB10, SPB20, SPB30, SPB30+

-

Efficient drying of sawdust, wood chips, biomass, agro materials & minerals

-

Compatible with KD and UNI hot-air boilers

-

Ideal for medium to large industrial plants requiring flexible configuration

SPB Compact Series – Space-Optimized Drum Dryers

-

Same SPB technology as the Standard Series, assembled on a steel frame

-

Fast installation and reduced site preparation requirements

-

Compact footprint for limited-space facilities or mobile installations

-

Supports all capacity models: SPB2 to SPB30+

-

Designed for quick deployment and simplified integration into existing lines

SPB UNI Series – Drum Dryers with UNI Clean-Air Boilers

-

Equipped with UNI heat-exchanger boilers for clean-air drying

-

Adjustable drying temperatures from 50°C to 480°C

-

Suitable for food-grade, agricultural, biomass, and impurity-sensitive materials

-

Optional combination with flue gases for higher heating efficiency

-

Available as Standard-UNI or Compact-UNI configurations

Comparison of SPB Variants

A quick overview to help customers select the most suitable configuration.

Material Compatibility & Capacity Range

SPB drum dryers are engineered to process a wide spectrum of bulk materials commonly found in the wood, biomass, agricultural, recycling, and mineral industries. Thanks to their robust design and stable thermal performance, they ensure uniform and efficient drying of wood sawdust, wood chips, biomass, pellets, bark, and other wood-based residues, making them ideal for pelletizing and briquetting lines.

In agricultural applications, SPB dryers reliably handle cereals, grains, legumes, corn, fodder, grass, hops, hemp, and other agro commodities that require moisture reduction before storage or further processing. Their continuous rotary-drum system maintains consistent airflow, allowing even moisture levels across diverse particle sizes — from fine sawdust to coarse agricultural mixtures.

For heavy-duty and construction materials, SPB dryers are suitable for sand, gravel, mineral aggregates, cement-based materials, calcium materials, and plastic regrind, providing stable drying performance even with abrasive or moisture-sensitive raw materials. This versatility makes the SPB series a practical solution for both small-capacity producers and large industrial plants seeking reliable, high-throughput drying technology.

Additional Accessories & Enhancements

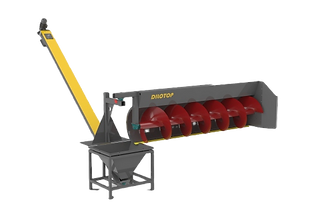

Collecting Feed Screw Conveyor

-

A floor-level screw conveyor designed for continuous feeding of SPB drum dryers.

-

Ensures automatic and steady filling of the drying drum without manual supervision.

-

Ideal for processing sawdust, wood chips, biomass, agro materials, and other bulk feedstocks supplied directly from the floor area.

-

Improves line efficiency by eliminating material interruptions and preventing uneven dryer loading.

-

Recommended for installations requiring uninterrupted material flow and stable drying performance.

Cyclone spark and dust separator

-

A centrifugal cyclone separator that removes coarse impurities, ash, and sparks from flue gases.

-

Improves boiler efficiency and protects downstream components.

-

Reduces dust emissions and enhances overall air quality.

-

Recommended for applications where flue gases are used to increase drying temperatures.

Electrostatic separator of sparks and dust

-

Uses an electric field to capture fine dust, ash, and sparks, ensuring up to 90% filtration efficiency.

-

Ideal for reducing emissions and meeting stringent environmental standards.

-

Can be combined with a cyclone separator for maximum air purification.

-

Helps maintain a cleaner and safer work environment.

Automatic Ash Removal

-

External Ash Container – Collects ash efficiently for easy disposal.

-

Screw Conveyor System – Transports ash automatically from the combustion chamber.

-

Reduces manual cleaning, ensuring continuous operation with minimal downtime.

-

Available with a large-capacity (0.5 m³) storage unit for extended maintenance intervals.

Control System with Automatic Regulation

-

Siemens-based HMI control system for managing all key functions of the SPB dryer line.

-

Allows operators to set required parameters and switch the equipment into full automatic operation.

-

Provides real-time monitoring of material input, hot-air boiler, drum dryer, and material output.

-

Ensures stable drying performance while allowing manual intervention whenever needed.

-

Designed for safe, reliable, and user-friendly operation of the entire SPB assembly.

Contact Us for more information

Interested in a custom SPB drying solution?

We provide complete project design, performance calculations, and technology integration.